Value Chain Optimisation

Gain valuable insights and benefit from visibility across the entire value chain, in a unified environment – from planning to scheduling to inventory.

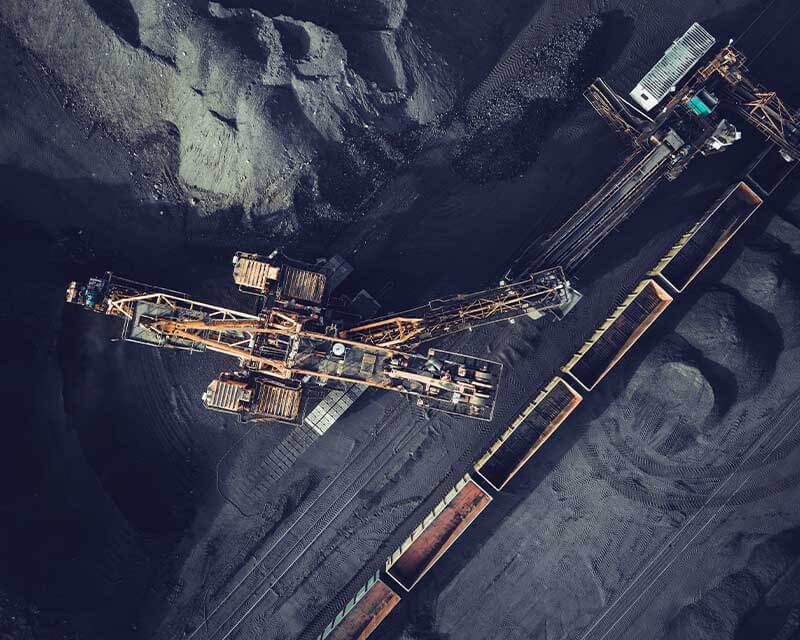

Asset Performance Management

Master the tools that can predict potential equipment failures. Digitalise your procedures and maintenance activities.

Production Optimisation

Transform data into insights with process optimisation, delay accounting and downtime analysis.

Next-Generation Workforce

Gain foresight into potential equipment failures. Digitalise your procedures and maintenance activities.